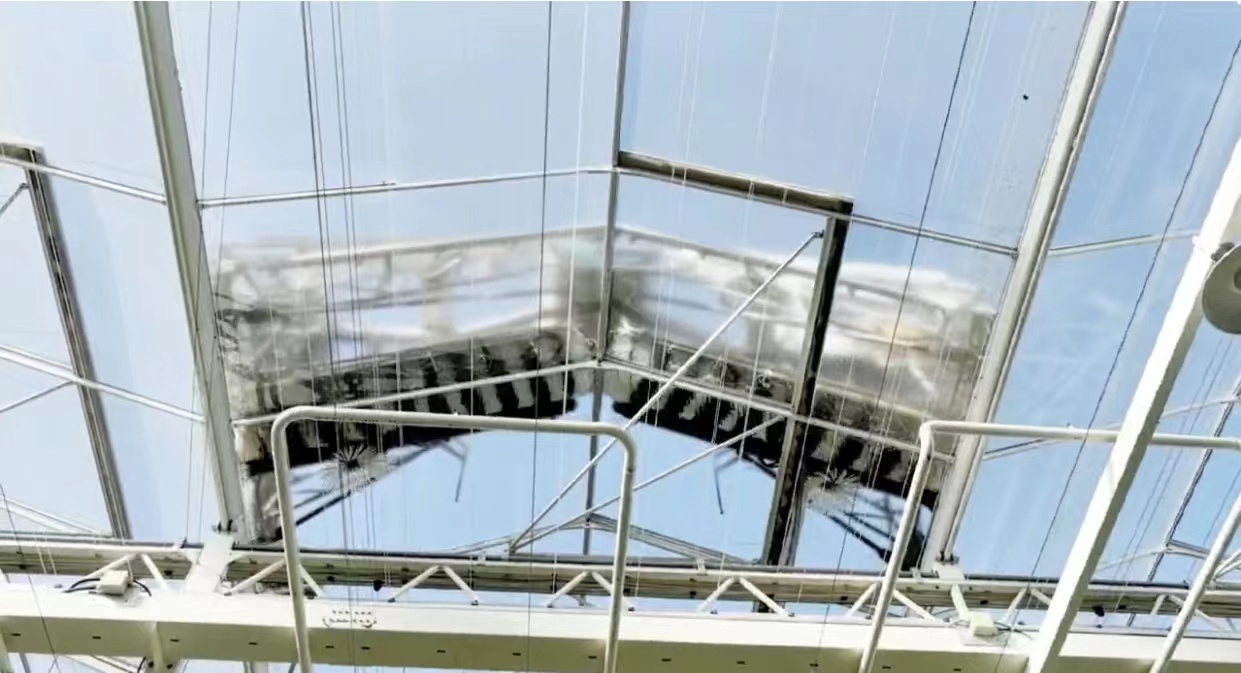

The cleaning machine mainly adopts the design of on-site assembly of structural components, which is roughly divided into two inclined side beam structures, inclined side beam overlapping structures, wheel drive structure groups, rolling brushes, pressure water injection systems, structural support and confinement components, and electrical control organizations. The structural components are made of aluminum alloy, alloy profiles, and some stainless steel structural components. In terms of force calculation, it is a consideration that spans both force and friction. The connection and transportation of the loading platform is quite complex, as it is responsible for the high-altitude transportation (left and right movement) of the cleaning machine, as well as the coordination work of loading and cleaning machine operation positioning. This design requires detailed on-site measurements of the greenhouse, especially involving the lubrication of the sliding rails and the design of the moving drive wheels. The platform roughly includes ladders, support beams, ground support wheels and greenhouse C-side drive wheels, slide rail buckle components and platform structure, and electrical control parts. The design should be fully developed according to the support structure device for high-altitude operations, with a focus on the surplus coordination between safety and assembly connection.

Based on some of our design and on-site application experience, there are several complexities to this cleaning system. Firstly, the precise assembly amount coordination between the structure during the mechanical design process, especially considering the deformation during the assembly and overall operation of the structural components, resulting in the overall operation of the fresh machine and platform, as well as structural changes such as running lag and multiple disassembly and assembly. The second is the adjustment of the installation position of electrical control components, especially the sensing position, interference obstruction during the overall operation process, and the functional bottom limit value of the components. The third is the programming work of PLC, which is the coordination of software systems, which is a soul work. The fourth is the quality of the pressure pump, water pressure pipeline, circuit, and motor, as well as the wear and rotation of the positioning drive running wheel without deviation.

The workflow of the complete cleaning system; The transport platform is located in front of the ridge of the glass greenhouse to be cleaned. The limit device is controlled and connected to the drainage ditch at the top of the greenhouse. The roof cleaning rack is located on the roof. The roof cleaning machine automatically operates (moves) in the drainage ditch. The water and electricity hose reel starts the retraction and retraction action, and the roof cleaning machine runs and cleans according to the movement distance.